Getting Implant Application Correct

Dr. Warren Rusche is an

Extension feedlot specialist and assistant professor at South Dakota State University.

How would you like to make a few thousand dollars per hour (legally)? Numbers like that get people’s attention but might also trigger a “if it sounds too good to be true it probably is” response.

When cattle backgrounders and feeders use growth promoting implants correctly those returns are not a pipe dream. Consider that implants can increase ADG by 20% in growing cattle. A set of backgrounded steers that would have gained 2 pounds per day non-implanted now should gain 2.4.

Over a 100-day feeding period the additional 48 pounds of liveweight could be worth an additional $40 to $50 per head, depending on the price slide. Implants in feedlot cattle increase carcass weight by approximately 80 pounds, representing an additional $120 to $150 per head. The fact is that implanting cattle correctly offers more return for time invested than almost any task in cattle feeding, with the possible exception of tarping the silage or high-moisture corn pile.

The key is administering the implant correctly. That is especially true when using one of the longer-acting implants such as Revalor-XS or -XH or Synovex One Feedlot where there is only one opportunity to accomplish the task correctly. Reviewing implanting procedures is an excellent opportunity to make certain that everyone on the team understands the importance of the process and what needs to be accomplished.

What tools are needed?

Making sure that all the necessary equipment is on hand helps make sure that there are no unnecessary delays and to increase the odds that every animal is implanted correctly. Here are some items that should be on hand:

• Extra needles, possibly a backup implanting gun

• Scraping tool to remove dried mud

• Brush to clean ears

• Tray to hold disinfectant solution

• Disinfectant

Cleanliness is the first step.

Remember that we are inserting a foreign body into the animal, so any contaminants on the ear that are carried along with the needle increase the risk for abscesses.

Using a brush dipped in disinfectant to remove external contamination reduces abscess risk, especially in wet or muddy conditions.

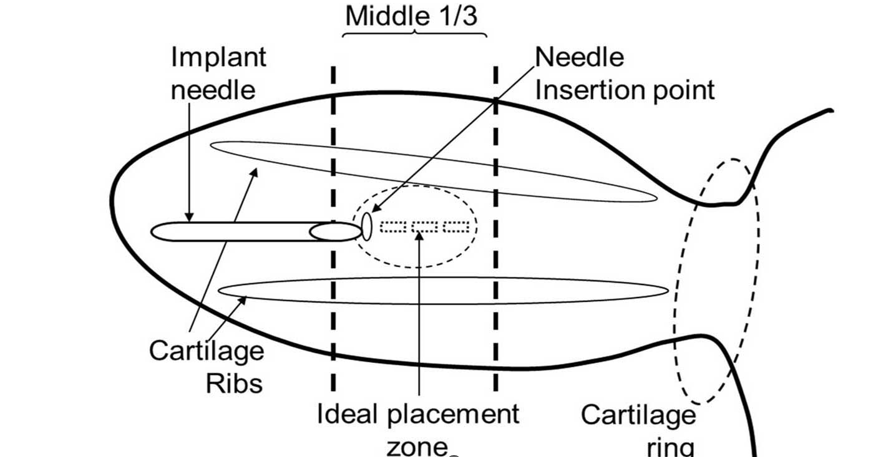

Place the implant in the correct location.

Implants need to be placed in the middle one-third of the ear under the skin. The location may be moved to alternative sites above or below the cartilage ribs to avoid ear tags or tissue damage, if necessary.

Avoid placing in blood vessels or cartilage. Either mistake negatively affects how the animal responds to the implant.

Avoid crushing the implant.

Some newer implanting guns on the market automatically withdraw the needle as the trigger is depressed, reducing the risk of crushing the implant. Some guns require the operator to partially withdraw the needle while depositing the implant pellets.

Crushed implants release too rapidly, increasing the risk of bullers or negative effects on carcass quality.

It is a good idea to run your finger over the implant and squeezing the needle hole shut prior to releasing the animal. This gives an opportunity to correct a missed implant and to help prevent pellets from working themselves out.

Clean equipment before the next animal.

Wiping the needle in a sponge soaked in a disinfectant solution removes any contamination that may have come from the last animal and reduces the risk of transferring that to the next.

At the same time, check the needle on the gun to make sure that the end has not developed a burr or other defect.

Defective needles increase tissue irritation and should be replaced as soon as they are noticed.

Use ear audits to monitor performance.

A great way to make sure everything is on track is to check for proper implant placement. This could be a planned audit where about 20 head are pulled from their home pen three weeks after implanting, or a more informal process where cattle are checked the next time they are brought to the chute. Even experienced processing crews can benefit from refreshers and periodic checks.

Tips for Dealing with Wet, Muddy Feedlot Conditions

Could BRD Cases Decline In High-Risk Cattle With Delayed Vaccination?

Beef Cattle Implant Changes: What You Need to Know

Categorizing Feedlot Cattle for better BRD Management