Campfires > Combine Fires

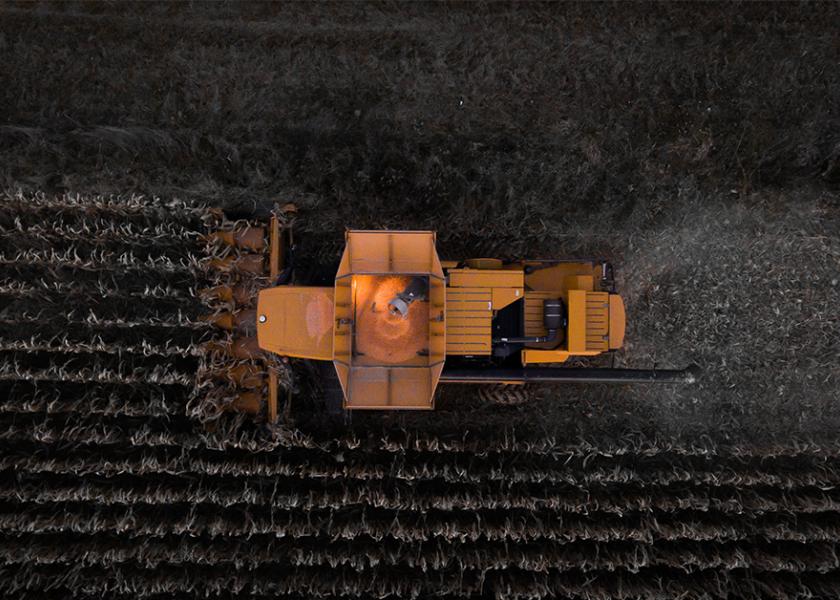

Large machinery fires — including those on and in farm combines and harvesters — cause around $20 million in property losses, untold millions in lost productivity and up to 50 serious personal injuries every year. But they can be prevented with attention to the three components of farm combine fire safety.

“Think in terms of how important prevention, detection and suppression all are to keeping your farm operation in business,” said Nationwide Agribusiness Business Development Director Kelly Grummert. “The whole goal of all three components of combine fire safety is to prevent machinery loss, protect the operator and ensure they all go home to their families every night.”

1. Inspect your combine harvester to minimize fire risk

Attention to fire safety starts well before a farm combine or harvester wheel turns. It starts at the farm shop or wherever a machine is stored year-round. Add the following to your routine post-harvest maintenance inspections to minimize fire risks:

- Clean crop residue or engine fluids like fuel or grease around the machine that could easily ignite in the presence of an external heat source.

- Clear plant material from bearings, belts and other potentially heat-generating components.

- Follow manufacturer’s recommendations for maintenance and lubrication prior to storing your harvester for a long period of time, paying close attention for potential leaks in hoses or fittings.

- Make sure your machine is stored away from external heat sources like furnaces or other heating elements that can lead to fire.

2. Monitor equipment for excessive heat

Fast forward a few months to harvest; once ready to hit the field, that’s when your farm combine or harvester safety should broaden to include fire detection and notification.

Advancing sensor technology available today can monitor heat generated around key components to ensure they’re within operating temperature ranges and aren’t creating enhanced fire risk.

“If it’s getting too hot, it will alert the farmer so he or she can take quick action to prevent that overheating from developing into a fire,” Grummert said. “We’re looking at sensors like these as ways to cut down significantly on harvester losses and the risks they create for the machine’s operator. This technology is helping us become better at fire detection when a machine is running in the field at harvest.”

Thermal imaging can also help with fire detection. Because equipment can show problems in the form of excessive heat before they fail, early identification of anomalies is a critical step in preventing possible combine fires.

3. Be prepared by equipping your combine tractor with fire extinguishers

A combine or harvester can go up in flames in a matter of minutes. If you’ve detected an overheating component or small fire early on, you can still take action to prevent it from engulfing the machine. Make sure you have fire extinguishers both in the cab as well as near likely trouble spots around the machine so you can take quick action. And make sure they’re inspected and in working order at all times.

“The whole goal of prevention, detection and suppression on these machines is to avoid the loss, protect the operator and ensure no one is hurt or worse,” Grummert said. “We want to help farmers prevent these losses so they’re safe, don’t experience interruptions at harvest and can keep trucking along in a hugely important time for most operations.”

Complete a combine fire survey

The Iowa State University capstone design team is working on the development a fire detection and suppression system for combine harvesters. They have created a short, online survey to gather valuable input from farmers about system features and their experience with combine fires. Start the Combine Fire Survey.